XK-800/XK-1000 Three-Sided Paper Bag Sealing Machine is a kind of packaging machinery and equipment widely used in many industries such as food, medicine, chemicals, daily necessities, etc. It is characterized by the function of automatic sealing.

Three-side sealing paper bag machine is a kind of packaging machinery and equipment widely used in many industries such as food, medicine, chemical industry, daily necessities, etc. It is characterized by the function of automatic three-side sealing.

The three-side paper bag sealing machine enables efficient packaging production. Due to its high degree of automation, easy operation of the equipment, and rapid production and automatic sealing of packaging bags during the production process, it can greatly improve production efficiency and save time and labor costs.

Secondly, the device is easy to operate and has high reliability. The three-side sealing paper bag machine can automatically complete the production and sealing of packaging bags through electrical control and pneumatic control. Its operation is also very simple and convenient, without cumbersome debugging and maintenance, so the reliability and stability of the equipment are very high.

At the same time, the device is flexible and expandable. The three-side sealing paper bag machine can be used to make bags of various specifications, such as paper bags with different lengths, widths and heights, plastic bags, etc. It can also be customized and expanded for different packaging needs to meet different production needs.

Three-side sealing paper bag machine is an efficient, reliable, flexible and easy-to-use packaging equipment, which has been more and more widely used and promoted in the modern packaging industry.

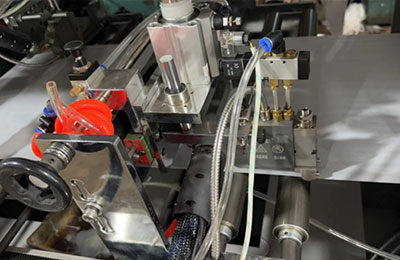

Machine configuration

1. Double feeding before and after, independent correction, automatic tension, no material stop and other functions;

2. Before and after discharge double traction, independent control;

3. The edge glue is coated by mobile hot melt glue and driven by servo;

4. The base glue is adjustable, and the hot melt glue is coated;

5. Two sets of heat sealing units make the sealing on both sides of the bag more uniform and firm;

6. The heat sealing unit at the bottom of the bag makes the glue coating at the bottom of the bag more uniform and firm;

7. Bag mouth self-adhesive unit, independent hot melt adhesive machine, servo transfer and release paper, make it run more smoothly;

8. Color calibration unit, accurate positioning and printing of color bags, so that each bag presents a unified standard;

9. Trimming knife, using the upper and lower round knife way, so that trimming more accurate, smooth, durable and so on;

10. Servo motor is used to drag materials accurately;

11. Cutting knife unit, using high speed, wear-resistant, hard alloy steel blade;

12. Conveying table, movable mode is convenient for batch bag handling, making the work easier;

13. The Three-Sided Paper Bag Sealing Machine frame adopts international standard steel plate, laser cutting molding, the Japanese assembly method, male and female buckle interpenetration screw locking, so that the strength of the fuselage to achieve the best state, two is not the traditional peer with channel steel plate welding, resulting in the fuselage strength is not enough, the service life is not long and easy to deformation;

14. Independent electrical control cabinet, equipped with man-machine interface.